QForm Forging Simulation Software

QForm is a professional engineering software used for simulation, analysis and optimization of metal forming processes providing excellent reliability. It covers the essential needs in metal forming simulation for large and small forging companies as well as research and educational establishments.

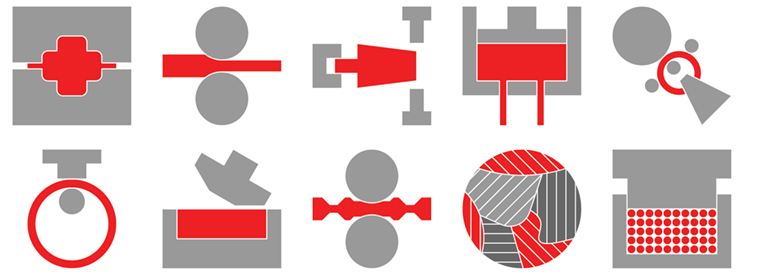

QForm is intended for simulation and optimization of

- Cold forging

- Warm forging

- Hot forging,

- Open die forging,

- Rolling,

- profile extrusion and other metal forming processes.

A variety of additional special modules such as

- Microstructure prediction,

- Heat treatment simulation,

- User subroutines assignment can be implemented in program.

New QForm VX is the latest development of our simulation software. It has the

- most user-friendly interface in the market,

- the fastest simulation time thanks to the most modern programming techniques

- wide functionality

- The very powerful and universal software core makes it possible to simulate any kind of metal forming processes.

- fully automatic and highly adaptive mesh generator.

QForm can simulate most metal forming processes and the variety of processes that can be simulated in QForm is continuously being extended thanks to the following features:

- coupled thermo – mechanical problem in Work piece-Tool system

- simulation of complex tools

- any number of instruments and work pieces in one simulation model

- forming of multiple work pieces of different materials

- simulation of spring loaded tool and load holder

- implicit and explicit integration method

- User defined functions (UDF)

- Special boundary conditions for work piece and tool

- Simulation of visco-plastic and elastic-plastic deformation

- Simulation of thermo-elastic-plastic problem

Powerful capabilities for modifying simulation parameters and finite element mesh

- Simulation results import from popular casting simulation software (ProCast, MagmaSoft)

- Direct interface with JMatPro software for creation of rheological models of materials and creating TTT and CCT diagrams for heat treatment simulation

- Interfaces with software for microstructure and phase transformations simulation (MatiLDa)

Finite element mesh generation and remeshing during simulation are carried out automatically and generally don’t require the user’s intervention.

QForm comes with a huge database of deformed materials, tool materials, drives and lubricants. There are models of mechanical, hydraulic and screw presses, hammers, rotational equipment and several friction models specified in the program.