Introduction

Sheet metal design is a critical component in various industries, including automotive, aerospace, electronics, and construction. The complexity of designing with sheet metal requires specialized tools that can handle a wide range of tasks, from initial conceptualization to detailed fabrication drawings. NX Sheet Metal Design Software, developed by Siemens Digital Industries Software, has become the go-to tool for many professionals. But what makes it superior to other tools available in the market?

Advanced Design Capabilities

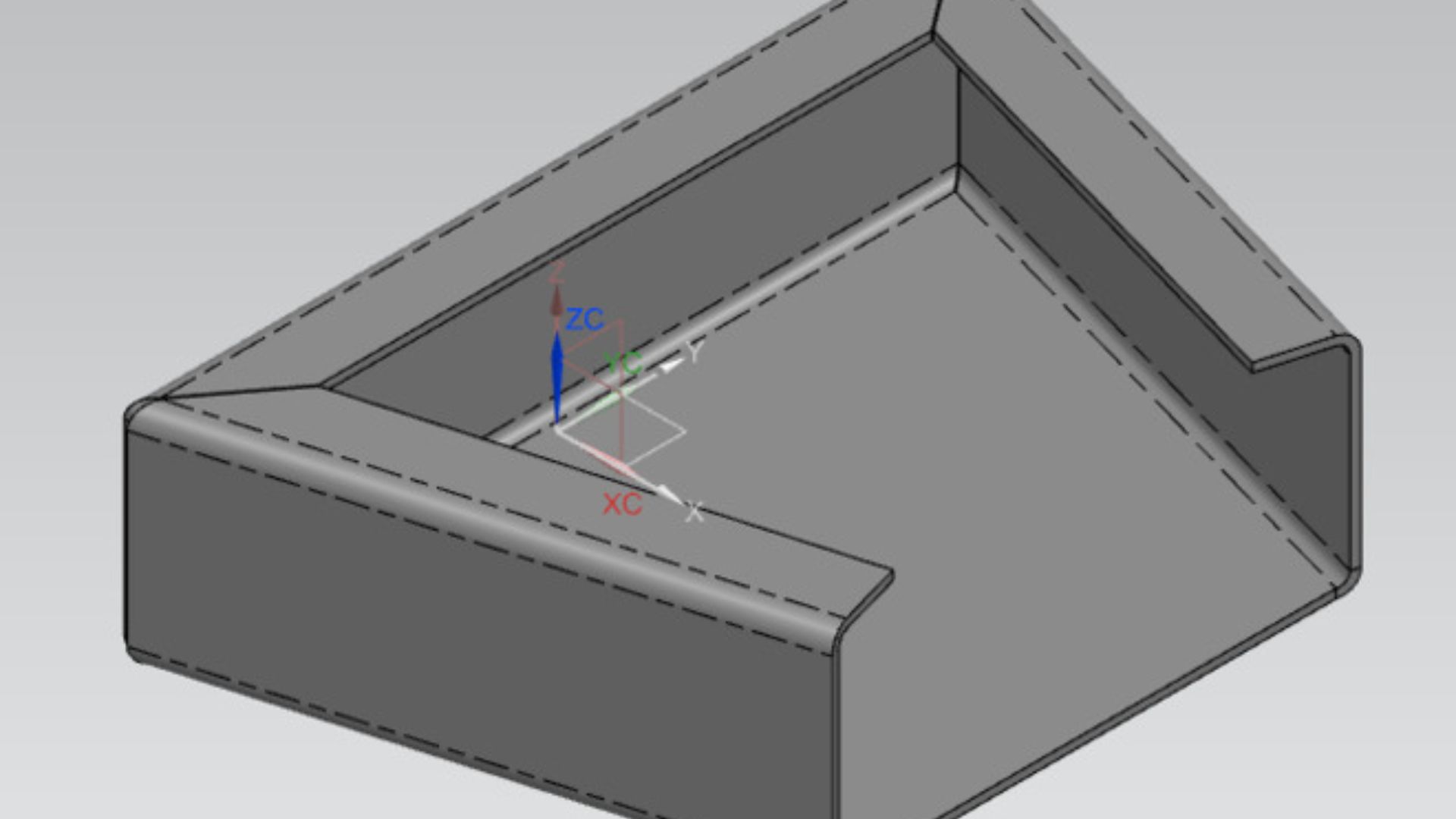

One of the primary reasons professionals choose NX Sheet Metal Design Software is its advanced design capabilities. The software provides an extensive array of tools that enable designers to create complex sheet metal parts with ease. It supports both traditional and non-traditional sheet metal forming processes, allowing users to design parts that meet precise specifications. The parametric design features ensure that changes can be made easily and accurately, which is crucial for iterative design processes.

Comprehensive Toolset

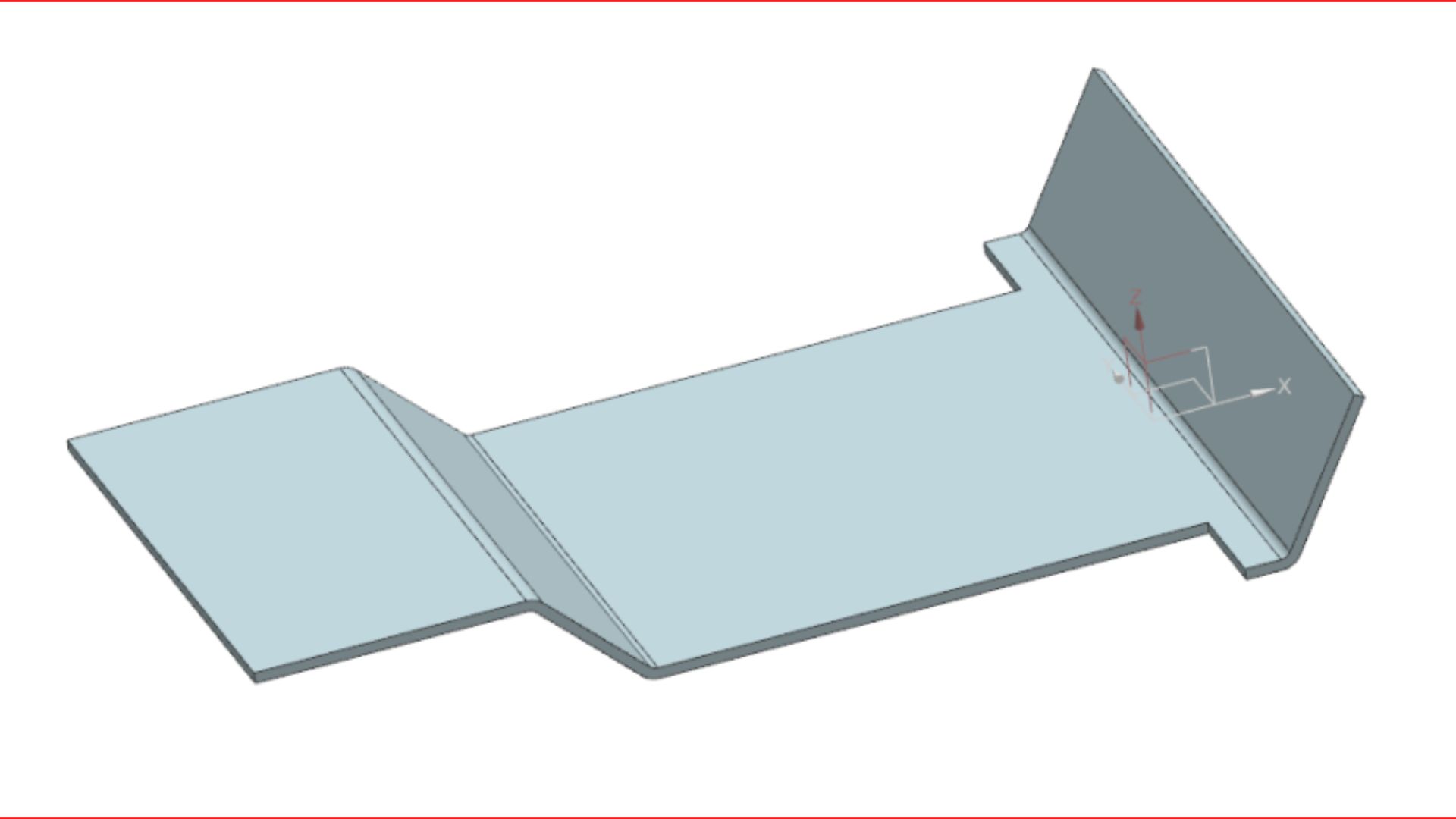

NX Sheet Metal Design Software offers a comprehensive toolset that addresses all aspects of sheet metal design. This includes features for creating bends, flanges, cutouts, and complex forms. The software’s ability to simulate real-world conditions helps in predicting how the sheet metal will behave during manufacturing, thereby reducing the likelihood of errors. Additionally, the integrated flat pattern creation tool simplifies the process of developing manufacturing-ready flat patterns from 3D models.

Seamless Integration and Interoperability

Another significant advantage of NX Sheet Metal Design Software is its seamless integration and interoperability with other NX modules and third-party applications. This allows for a streamlined workflow, where designs can be easily transferred between different stages of the product development cycle. For instance, a sheet metal part designed in NX can be seamlessly integrated into a larger assembly, analyzed for structural integrity, and prepared for manufacturing without the need for data conversion or rework.

Efficiency and Productivity

The efficiency and productivity gains offered by NX Sheet Metal Design Software are unmatched. The software’s intuitive user interface and powerful automation tools significantly reduce the time required to complete design tasks. Features like automatic feature recognition and design rule validation ensure that designs are manufacturable and adhere to industry standards. These capabilities enable designers to focus more on innovation and less on repetitive tasks, ultimately leading to faster time-to-market for products.

Conclusion

NX Sheet Metal Design Software stands out among other tools due to its advanced design capabilities, comprehensive toolset, seamless integration, and significant efficiency gains. These features make it the preferred choice for professionals in various industries. Moreover, partnering with DDSPLM Private Limited guarantees that your investment in NX is maximized, providing you with the support and expertise needed to stay ahead in a competitive market. Whether you are looking to enhance your design processes or ensure the manufacturability of your sheet metal parts, NX Sheet Metal Design Software, supported by DDSPLM, is the ideal solution.