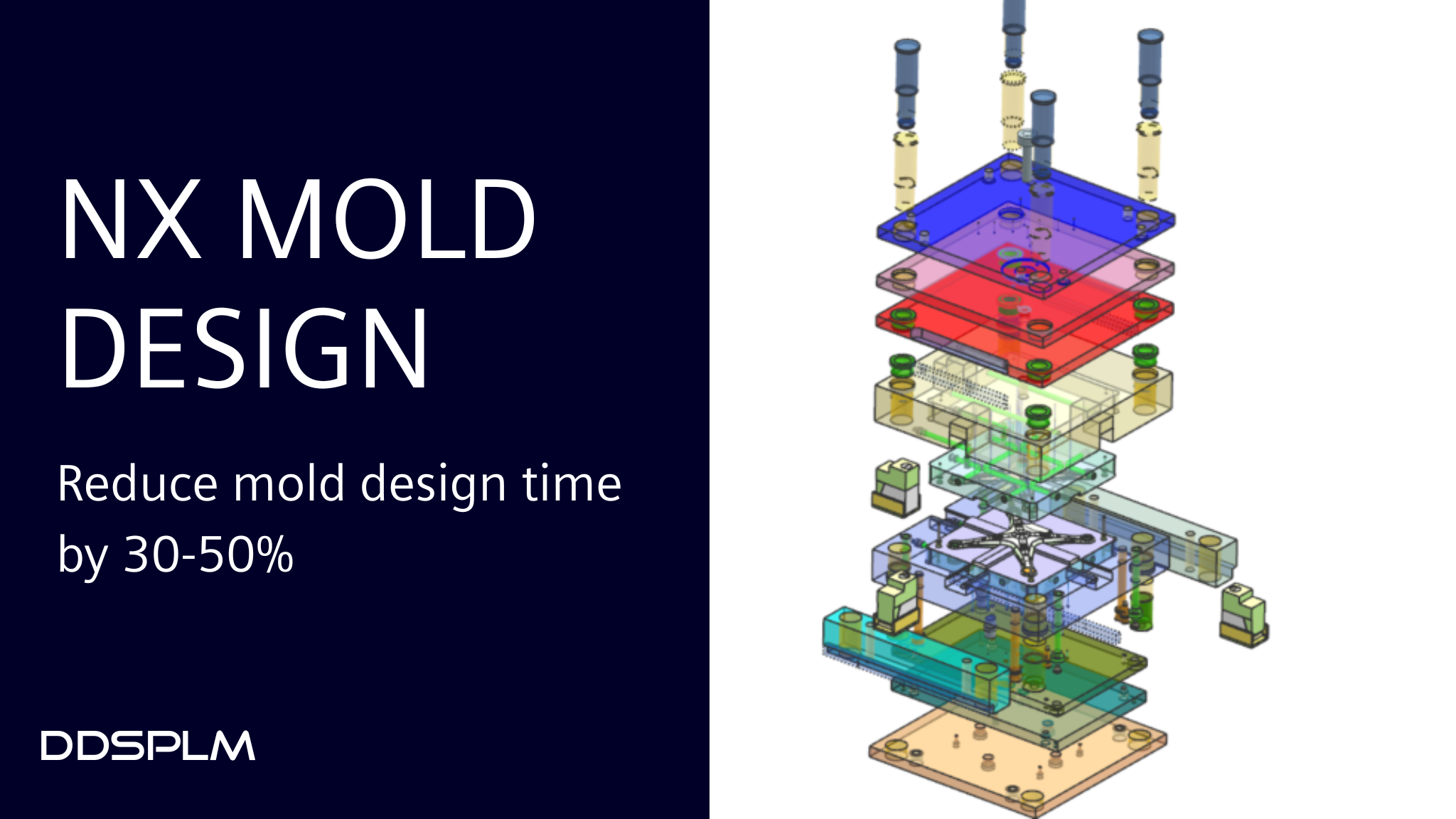

Revolutionize your Mold Design Process with NX Mold Wizard Faster, Smarter and More Accurate

The success in the contemporary high-paced manufacturing environment is determined by speed, accuracy, and efficiency. The pressure has to be always on the manufacturers of molds to produce great quality molds at a speed that does not affect the accuracy. That is where NX Mold Design Bundle comes in, which was specifically designed to support tool and mold makers with streamlining every part of the design process considering that it assists with up to 50 percent reduction of design time and quickening production.

The Reasons why NX CAD should be considered by Mold Manufacturers.

NX CAD with Mold Design is not a design tool but the entire digital manufacturing technology that companies designate are able to keep up with competition. It fills the divide between product design and production, allowing a smarter, quicker and more connected process of manufacturing moulds.

A small tool room or a giant manufacturing company, investing in Siemens NX Mold Design Bundle is investing in efficiency, innovations and growth.

The Actual Impact – cut in Lead Time and Cost.

The manufacturers who have utilized NX Mold Design have claimed a reduction of up to 50 percent in overall time dedicated to design and also considered a big saving of money due to automation and minimized errors. It is the integrated approach whether in design to manufacturing process that makes the work flow data consistent and shortens lead time and increases productivity.

With NX Mold Design, you can:

- Automatic detection and repairing of parting lines and undercuts.

- Create core and cavity design with very little handover.

- Have access to an enormous array of standard mold components.

- Design and simulation and manufacturing: seamlessly combined.

- State of the Art Features That Propel Productivity.

Automated Parting Design:

The NX is used to analyze the geometry of parts in order to detect automatically the problem of moldability, parts parting, and shut-off areas – minimizing manual re-work.

Mold Base: This is a library defining the components of a mold.<|human|>Mold Base: This is a library which outlines the elements of a mold.

There is no need to do repetitive modeling when using integrated libraries of standard parts (HASCO, DME, FUTABA, MISUMI, etc.). Just drag, drop, and assemble.

Early detect catch errors using inbuilt interference checks, motion validation and mold flow simulation – this way what was designed will be perfectly functional in the production process.

NX Mold Design Bundle enables the use of automation, standardization, and digital validation to allow the mold manufacturers to:

- Reduce mold design time by 30-50%

- Reduce lead-time and boost throughput.

- Reduce manual mistakes and redesigning.

- Increase the quality of products and life of tools.

Conclusion:

When you are a manufacturer of molds and you want to get more efficient, then NX Mold Design Bundle is not a simple upgrade, it is a game changer. With automation, standardization and smart design tools, Siemens NX gives your team the strength to create high quality molds with greater speed and efficiency than ever in the past.

Are you ready to speed up your design of the molds?

NX Mold Design can change your manufacturing process, arrange a free demo or consultation to find out how.