Digital twins, AR/VR bring simulation benefits to industrial automation users

A recent article published by The Robot Report, “Digital twins, AR/VR bring simulation benefits to industrial automation users, says Siemens,” describes how the convergence of digital and physical worlds, as manifested in simulation and robotics, provided manufacturers with the tools to adapt and even thrive amidst the challenges posed by COVID-19 this year. Siemens’ Vincent Guo, Ph.D., director of business development, strategy and portfolio management, for digital manufacturing, offered insight about trends around digital twins and AR/VR.

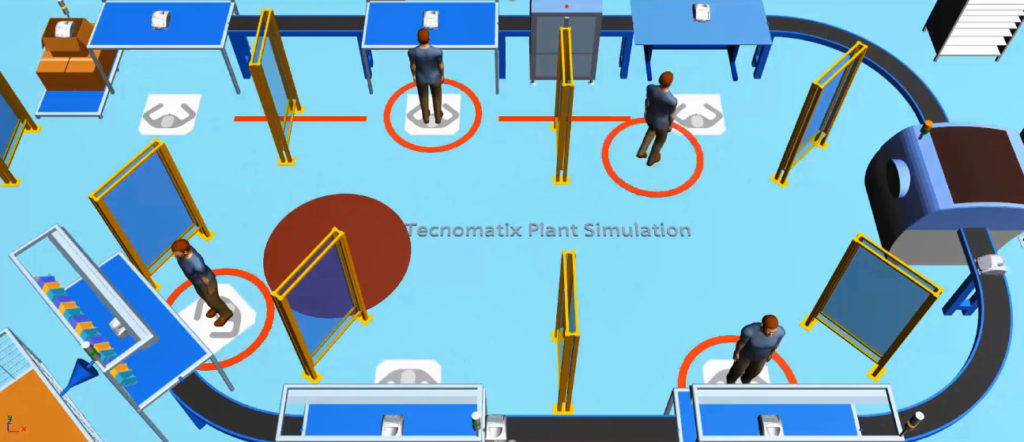

“Digital twins can help a newly automated company understand feasibility, estimate potential improvements, and reduce risk during implementation, just to name a few benefits,” Guo said. “Like CAD tools, the digital twin of production evolved from 2D to 3D. Today, simulations can be viewed in VR, supporting remote collaboration. With more elements being integrated into the simulation, what once started with pure mechanical simulation based on time sequences now adds electrical signaling to validate the control logic.”

Furthermore, he stated: “The need for digital twins has increased. As customers reduced their physical presence, digital methods to facilitate manufacturing design, deployment, and operations went from “nice to have” to “must have.” Siemens has had customers tell us they wish software deployment in their companies happened earlier. For instance, plastic-injection mold company iMFLUX used a Siemens digital twin to quickly retool for making COVID-19 tests.”